Motor Core Loss Explained: Silicon Steel Sheet, Stator Lamination, etc.

Core loss, also called iron loss, is one of the three main types of energy loss in a motor, along with copper loss and windage loss. The performance of the motor core is influenced by several key factors:silicon steel sheet、stator lamination、motor design、motor speed.

1. Material

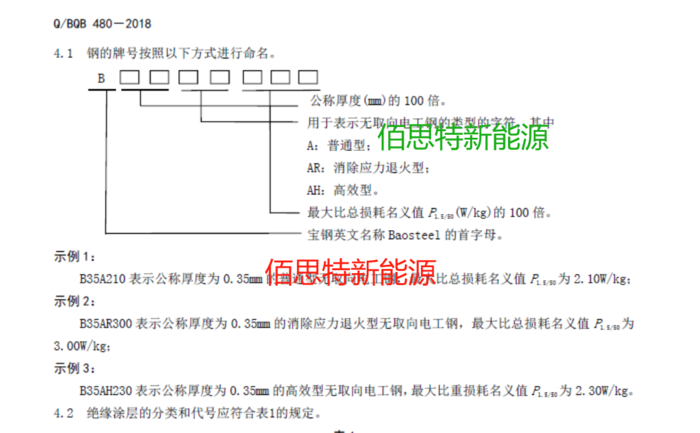

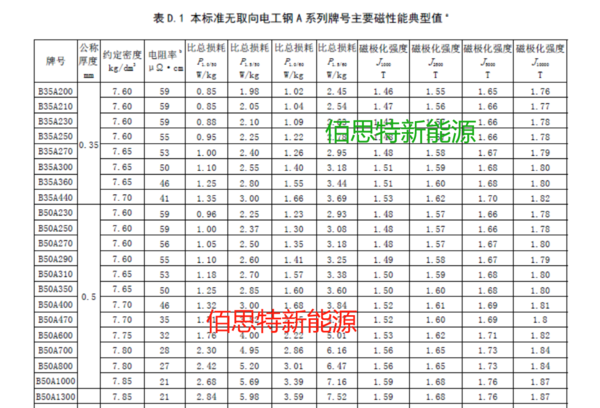

Motor cores are typically made by laminating cold-rolled silicon steel sheets. Iron loss is a critical indicator of silicon steel sheet performance, and the grade of the sheet is determined by its iron loss value. For example, Baosteel’s non-oriented silicon steel sheet B35A250 has a core loss of 2.5 W/kg under 1.5T@50Hz. Lower grade numbers indicate lower losses, better material performance, and higher cost. Selecting high-quality silicon steel sheet is essential for minimizing core loss.

2. Lamination Process

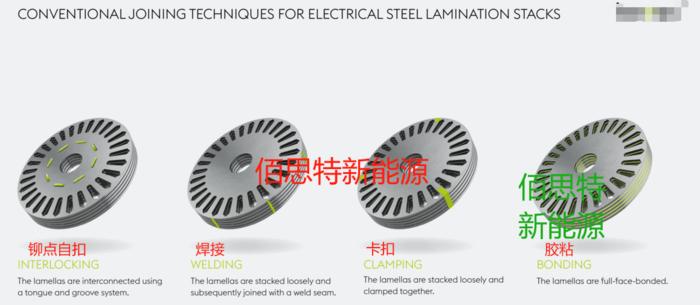

The lamination process directly affects core loss. Common methods include self-locking rivet points, welding, gluing, and clamping strips. Different processes lead to different loss values. For instance, in glued lamination, the eddy current loss caused by inter-layer conduction is effectively eliminated. High-end motors often use glued cores for improved efficiency. Best has years of experience producing glued cores and is one of the few domestic manufacturers capable of mass-producing bonded cores.

3. Motor Design

The design of the motor also impacts core loss. Factors such as the number of motor teeth, the arrangement of magnets, material selection, and winding parameters all influence the overall efficiency. Careful design helps reduce unnecessary losses in the core.

4. Motor Speed

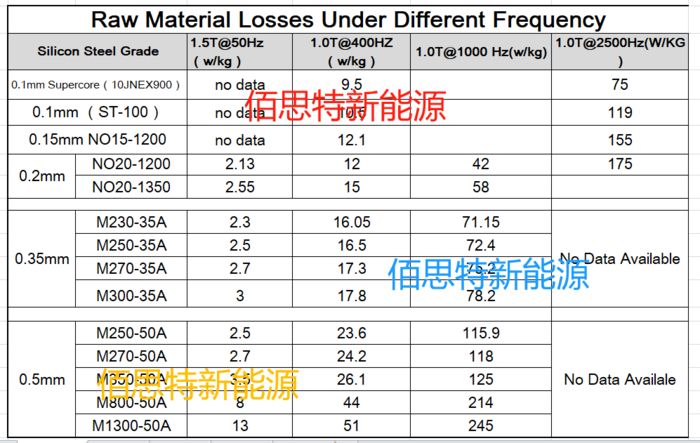

Motor speed directly affects the frequency, calculated as speed × number of pole pairs / 60. Eddy current loss is proportional to the square of this frequency, so higher-speed motors experience greater core loss if the silicon steel sheet thickness or grade remains the same. This is why high-speed motors commonly use ultra-thin sheets, such as 0.1mm super silicon steel.

Conclusion: Selecting high-quality silicon steel sheet, combined with optimized lamination processes and careful motor design, is crucial for reducing core loss and improving motor efficiency.