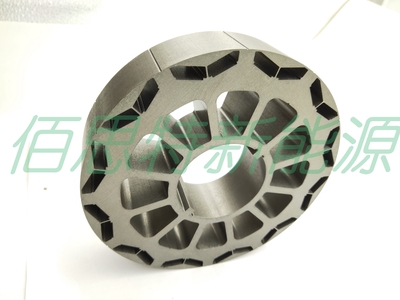

New Energy Vehicle Motor Core: Bonded Stator and Rotor Lamination

Motors in new energy vehicles are battery-driven, and efficiency directly affects driving range and market competitiveness. In high-speed operation, eddy current loss increases sharply because it is proportional to the square of frequency. To reduce this loss, thinner silicon steel sheets are commonly used. However, traditional welding or riveting during lamination creates interlayer conduction, which leads to additional eddy currents.

Bonded Lamination Technology

The bonded (glued) lamination process avoids interlayer conduction, thereby minimizing eddy current loss. This makes bonded stator and rotor technology especially suitable for high-speed, high-efficiency motors in new energy vehicles.

Best has focused on bonded stator and rotor cores for many years. We provide solutions for both manual and self-adhesive lamination, covering stamping, bonding, and testing, ensuring reliable support for high-performance motor core production.

Product Features

-

High stacking factor: 96%–98% with 0.2mm silicon steel sheet.

-

Certified adhesive: UL-approved, 200°C resistant glue ensures insulation and safety.

-

Low iron loss: Optimized processes help products meet material specifications, supported by test reports.

-

Noise control: Bonded lamination reduces vibration and noise compared with welding.

-

Surface protection: Adhesive film improves anti-rust performance.

-

Flexible capacity: Standard production of 100 sets/day for Ø200mm × H150mm stators, expandable up to 5× based on demand.

Technical and Production Advantages

-

Industry experience: Cooperation with several European and American NEV brands, supporting projects from prototype to SOP to mass production. Three projects are already in stable series production.

-

Thin sheet lamination expertise: 0.2mm silicon steel is widely used in NEV stators and rotors. Best provides full-process capability from sampling, mold design, stamping (350T high-speed press), bonding, to inspection.

-

Process options: Manual gluing solution with up to 97% stacking factor; self-adhesive solution at 94%–95%, chosen according to project requirements.

-

Progressive die development: Successfully developed Ø210mm stator and rotor progressive dies, ensuring deformation-free production with stacking factor above 97%.

-

Scalable production: Current daily output of 100 bonded stator and rotor sets, expandable by 3–5× with rapid personnel adjustment.

Bonded lamination technology offers clear advantages for new energy vehicle motors, helping to reduce eddy current loss and improve efficiency. With extensive experience, advanced thin-sheet stamping and lamination processes, and scalable capacity, Best provides reliable stator and rotor core solutions to global NEV manufacturers.