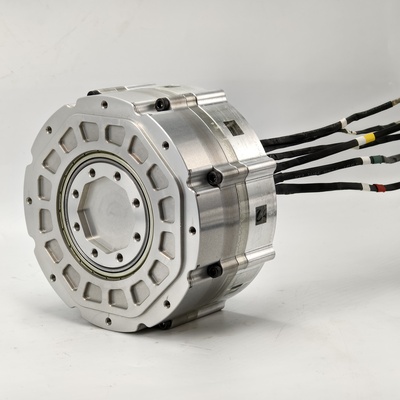

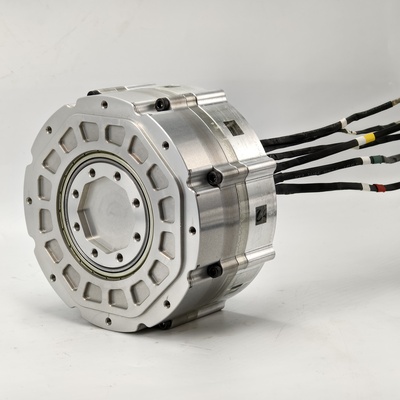

Axial Flux Motor: Compact, Powerful, and Efficient

Understanding Axial Flux Motor

Axial flux motors, also known as disc motors, are designed with a different magnetic flux path compared to conventional radial flux motors. Instead of a cylindrical air gap, they use a flat air gap, with the magnetic field aligned along the motor axis.

This design positions the rotor next to the stator, rather than inside it, which allows for a larger rotor diameter. The result is greater torque output and power density—up to seven times higher than traditional radial motors. These motors combine small size, high power, and strong torque, making them suitable for demanding applications where performance and efficiency matter most.

Main Advantages

-

High power density – up to 7x higher than radial motors

-

Space-saving design – compact structure with large torque output

-

Excellent efficiency – typically 82% to 99%

-

Wide application potential – meeting the needs of modern industries

Manufacturing Challenges

Despite their advantages, axial flux motors are still not widely mass-produced. The main reasons lie in their complex structure and production requirements.

Stator Core Production

Stator cores are usually manufactured from laminated silicon steel sheets or powder metallurgy materials. Since powder metallurgy has lower magnetic saturation, silicon steel laminations are the preferred choice for high-power, high-torque motors.

Our company has extensive experience in stamping and winding technologies, offering a wide range of customized stator designs, such as:

-

Double-sided stamping

-

Parallel slots and teeth

-

Chamfered or rounded tooth edges (ID & OD) for better flat-wire winding

Rotor Design

The rotor of an axial flux motor requires high strength and balance, as magnetic forces are less uniform compared to radial motors. To achieve this, rotors are often:

-

Wrapped with carbon fiber or overmolded with plastic to secure magnets

-

Designed with embedded magnets for added stability

-

Produced with advanced tooling for special assembly methods (e.g., dual-stator/single-rotor, dual-rotor/single-stator)

Cooling and Heat Management

Due to their compact structure, axial flux motors face more challenges in heat dissipation. To ensure stable performance, liquid cooling systems (water or oil) are often applied, which also adds to the structural complexity and cost.

Growing Applications and Market Outlook

With their higher efficiency, compact size, and excellent torque performance, axial flux motors are being adopted across more industries in recent years. The technology is developing rapidly, and the market demand is growing at an accelerating pace.

Our Capability in Axial Flux Motor Components

We specialize in the production of disc-type stator cores, stator assemblies, and rotor assemblies tailored for axial flux motors. With advanced stamping and winding processes, we deliver solutions that meet the requirements of different applications, helping our clients achieve reliable performance and faster product development.