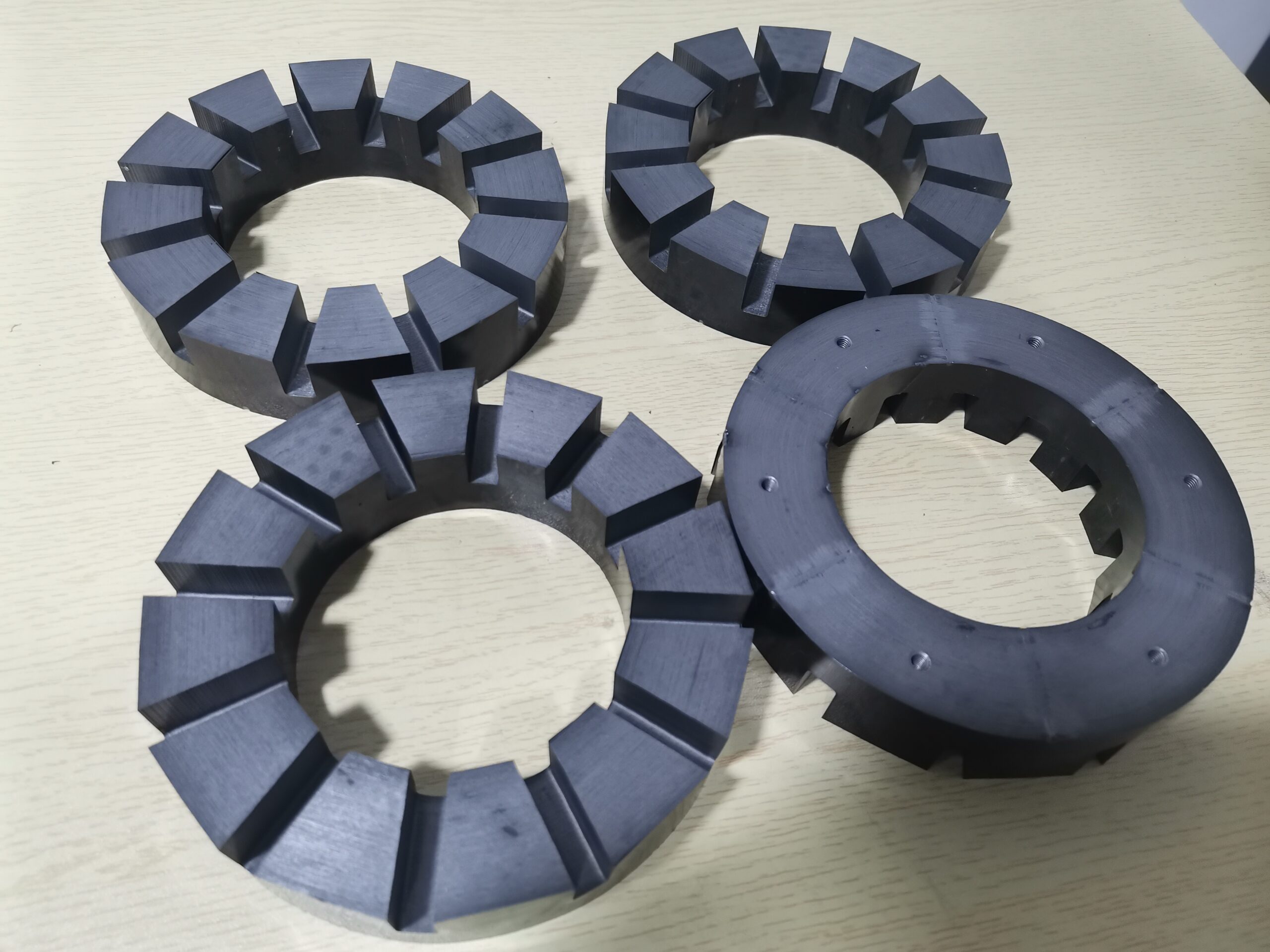

High-Performance Axial Flux Motor Stator Manufacturing and Technology

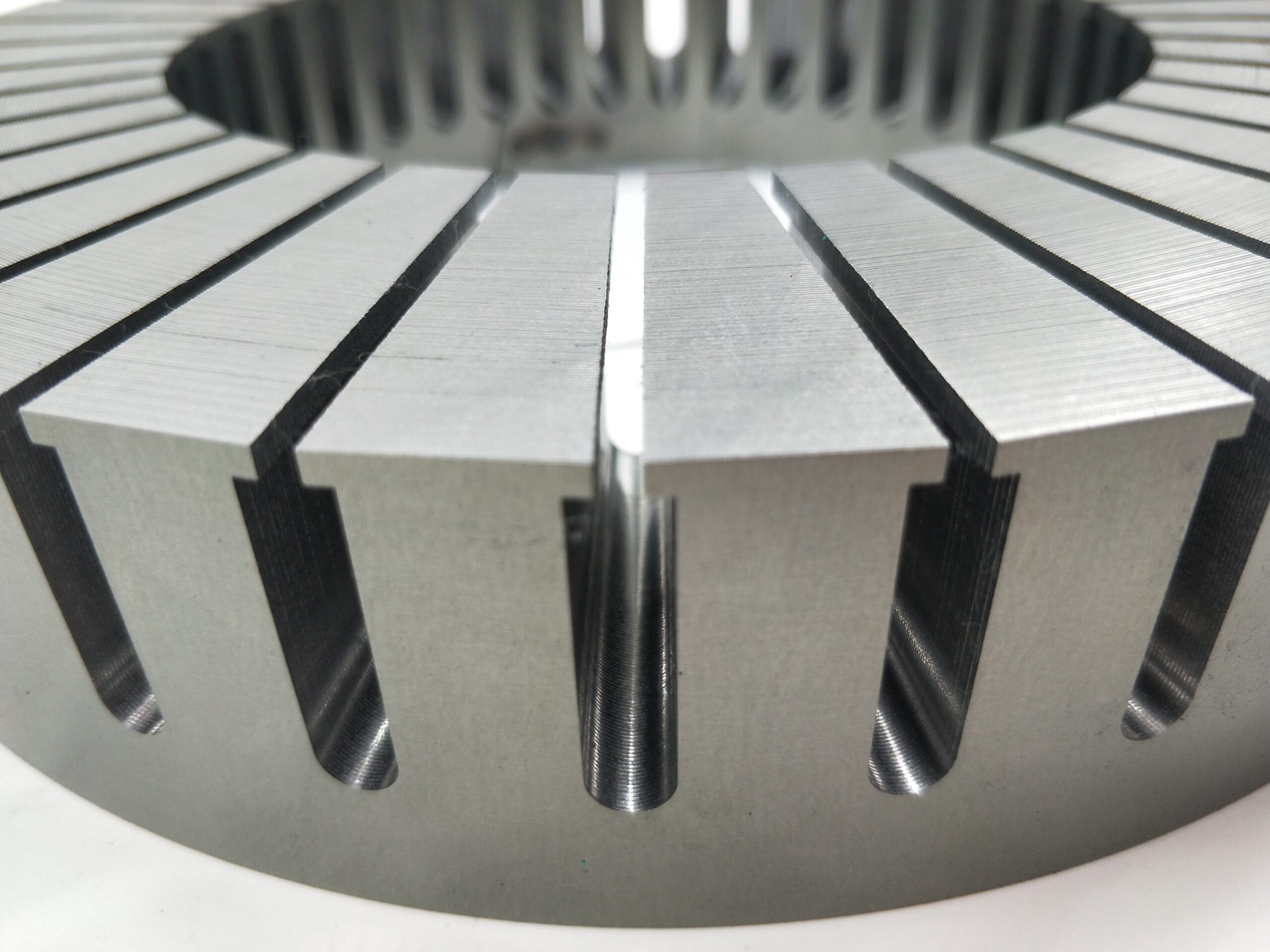

Double-Sided Punching Technology for Axial Flux Stator

In axial flux motor stator production, stamping and winding usually run as an integrated process. Each tooth is punched step by step while the servo system moves the coil stock forward. When teeth appear on both sides of the stator, manufacturers need special solutions:

-

Parallel tooth position – Engineers design an additional punch in the mold, allowing both teeth to be stamped at the same time.

-

Misaligned tooth position – As the winding radius increases, the distance between teeth also grows, making traditional molds unsuitable. In this case, a dynamic stamping die is used. The punch moves under precise computer control, ensuring accurate stamping results.

Best has years of experience in axial flux stator production. Our processes cover stamping, drilling, end-face grinding, annealing, and winding, delivering stable and reliable performance.

Stress Relief Annealing of Axial Flux Stator

Stress Relief Annealing of Axial Flux Stator

Stamping and laser cutting create internal stress on the silicon steel sheet’s cross-section. This stress disrupts the magnetic field inside the material and increases core loss. To solve this, manufacturers apply stress relief annealing after stamping. The process removes internal stress and restores better magnetic performance.

For high-performance axial flux stators, we recommend annealing treatment to reduce eddy current loss and improve efficiency. Best tailors annealing solutions to different grades of silicon steel sheet and supports them with years of production experience.

Stamping and Winding Process of Axial Flux Motor Stator

Axial flux stators are replacing traditional motors in many fields because of their compact design and high power density. Unlike conventional stators that use axial lamination stacking, axial flux stators are made with specialized stamping and winding systems.

Our process combines precision stamping dies with servo-controlled winding equipment. The system synchronizes stamping frequency and winding speed, keeping the inner and outer diameters aligned.

Best has independently developed six axial flux stator stamping and winding lines, producing up to 1,000 pieces per day. Because we design and control our own equipment, we can expand capacity by 3–5 times within two months.

We also provide one-stop axial flux stator solutions, covering raw material sourcing, stamping, winding, drilling, gluing, welding, annealing, and final assembly. Best now partners with several leading European motor brands, delivering reliable stator solutions for their advanced motors.

Polygonal Correction of Axial Flux Motor Stator

During stamping and winding, the stator teeth don’t form a perfect circle but instead create a polygon shape. The deviation becomes stronger on larger stators (over 200mm diameter) or when the tooth count drops below 24.

Best uses a unique correction method to adjust the polygonal arc and bring the outer diameter close to a true circle. This correction improves accuracy and boosts the performance of the final axial flux stator.