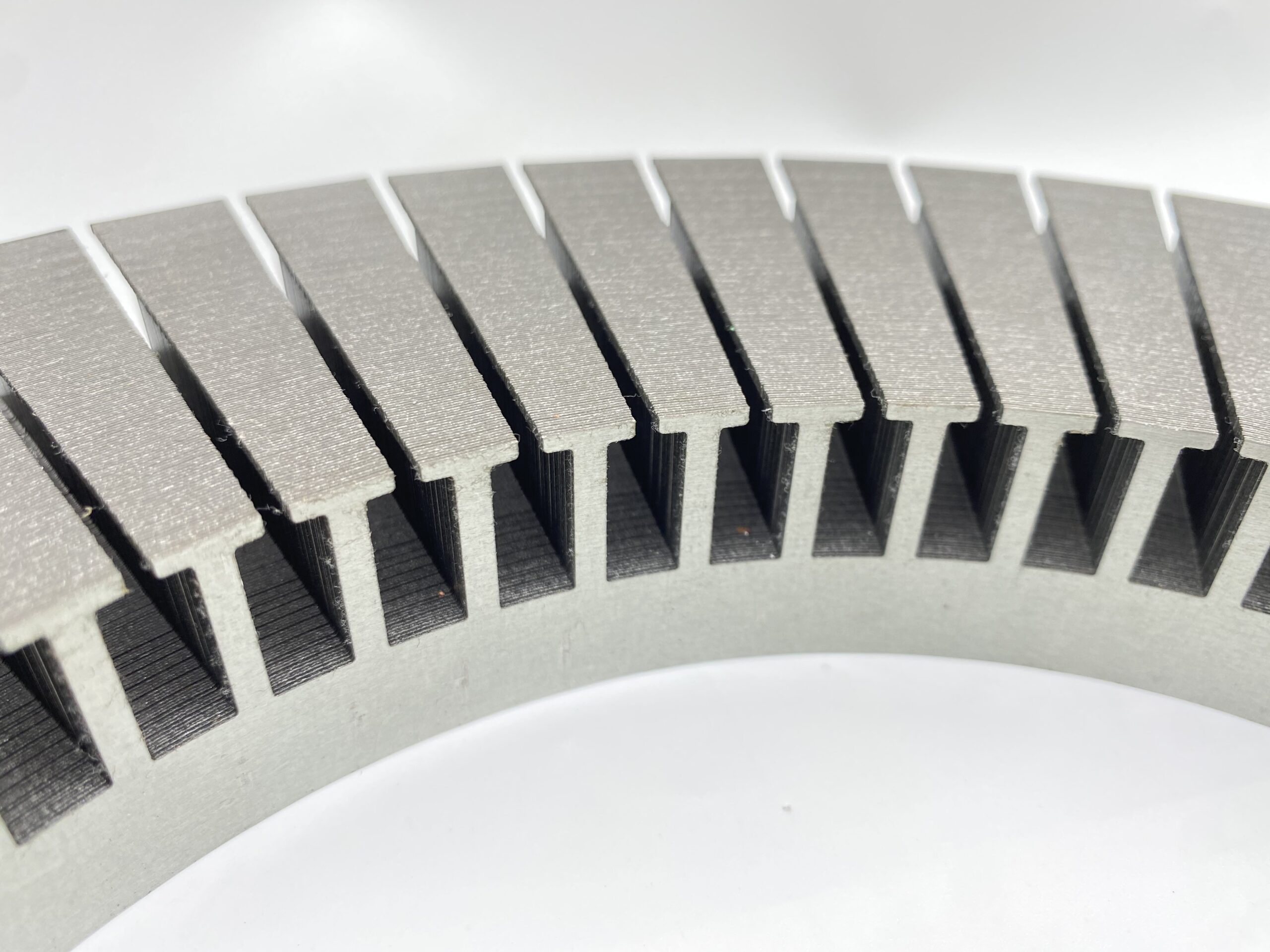

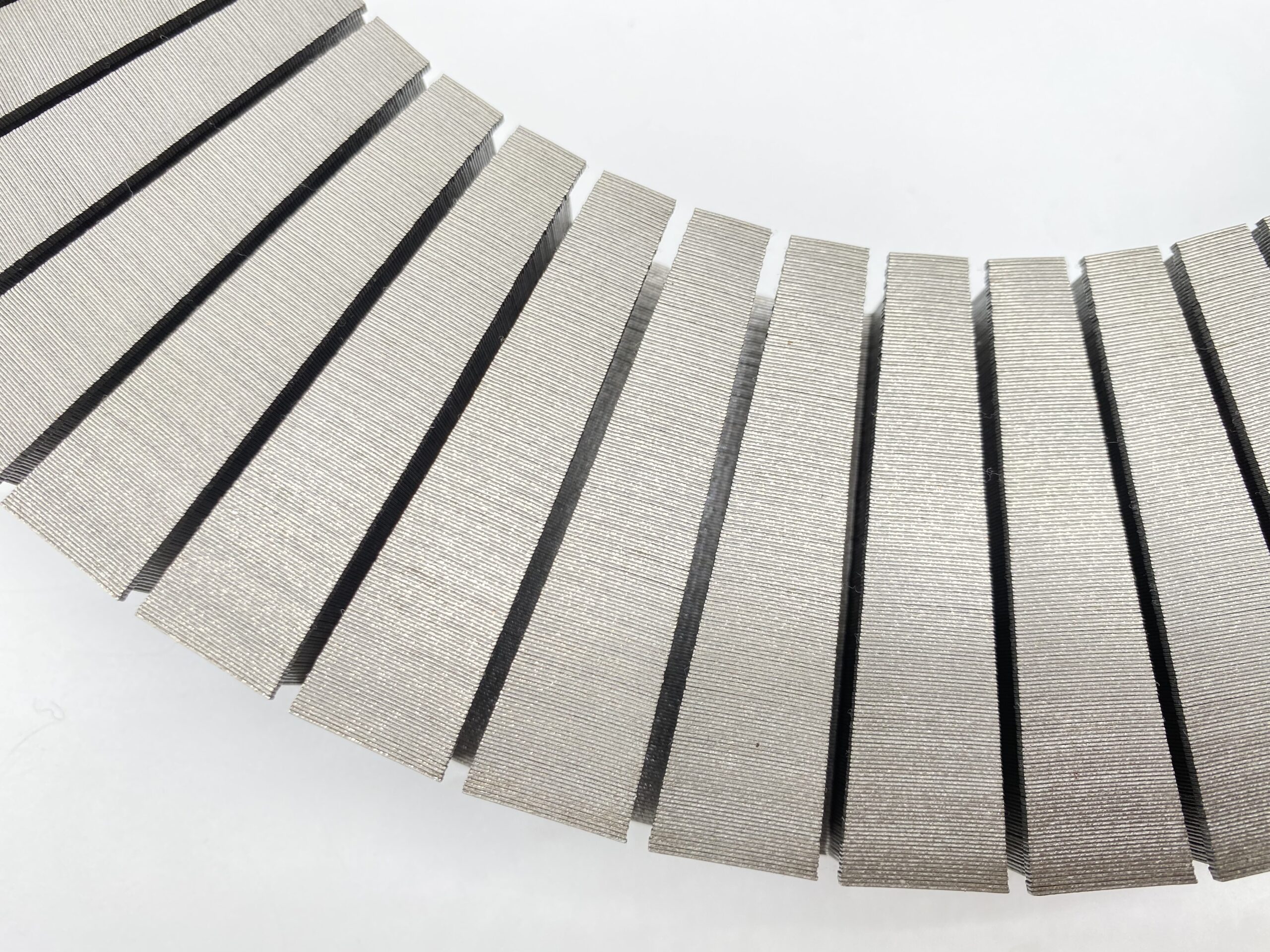

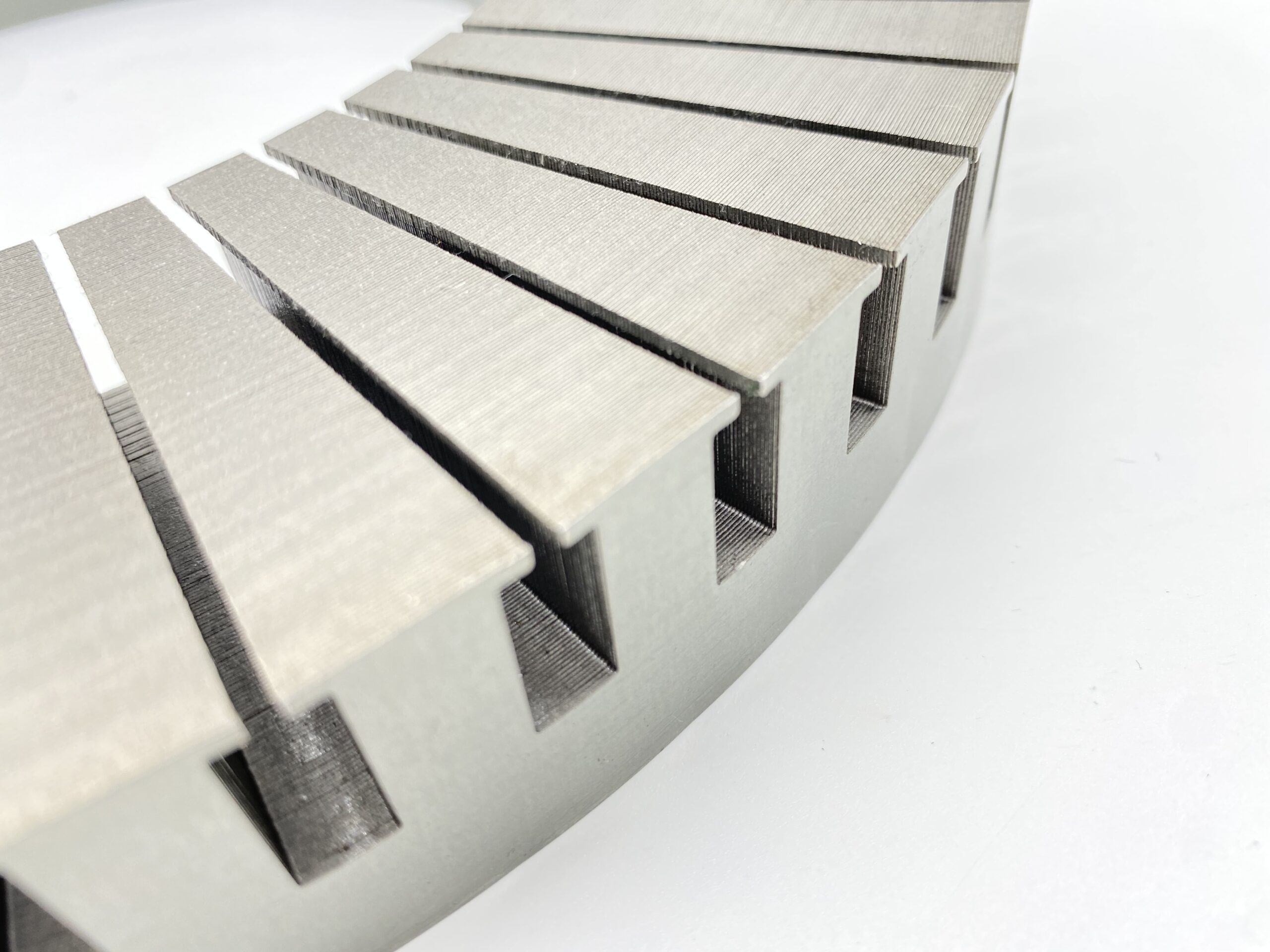

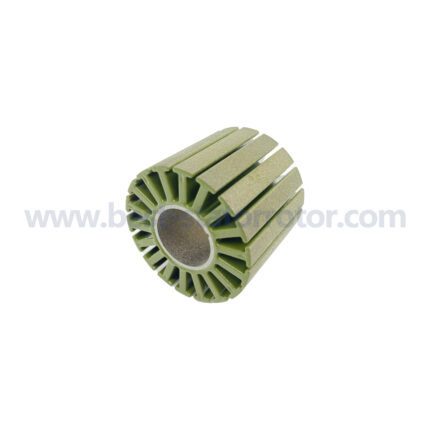

Axial Flux Motor Stator for High-Efficiency Applications

The axial flux motor stator has become one of the fastest-growing solutions in recent years. With its high efficiency, superior power density, and compact structure, it is replacing traditional motors across multiple industries. Typical application areas include wind power generation, lifting equipment, oil well exploration, and new energy vehicles.

Production Process

To ensure precision and performance, each axial flux motor stator is manufactured through a strict process:

-

Raw material preparation – premium silicon steel sheet is selected and segmented.

-

Stamping and winding – advanced equipment integrates stamping and winding with high accuracy.

-

Forming and welding/bonding – shaping and assembly to guarantee mechanical stability.

-

Drilling – precise finishing for stator alignment and durability.

Quality Control & Shipment

Every stator core undergoes a complete quality inspection before shipment:

-

Size inspection – 100% measurement beyond standard AOL sampling.

-

Appearance check – Our team visually inspects all products to ensure a flawless finish.

- Electrical performance test – We test all wound products before and after immersion to ensure maximum reliability and safety.

Packaging & Delivery

Best ensures safe international delivery of each stator:

-

Transportation – DHL, FedEx, UPS, and other leading couriers.

-

Inner packaging – rust-proof paper and oil treatment to prevent corrosion.

-

Protective wrapping – 20mm thick anti-collision pearl cotton for shock resistance.

-

Outer packaging – durable K-grade cardboard boxes or plywood crates for secure transport.

With strict production standards and reliable logistics, Best provides customers worldwide with axial flux motor stators that meet the highest performance and safety requirements.