Anti-Rust Treatment for Stator and Rotor

Rust can quickly reduce the performance and lifespan of motor stator and rotor cores if not handled properly.

With the right surface protection, these key components remain stable, durable, and reliable even in harsh environments. Our solutions include both standard anti-rust treatment and advanced electrophoretic coating (E-coating), ensuring long-term protection for your applications.

Why Rust Occurs

Silicon steel sheets used in stators are usually supplied with an insulating coating, which provides protection between layers and prevents corrosion under normal conditions.

However, after punching and shearing, the edges of the stator and rotor expose bare iron to the air. If no treatment is applied, rust will usually appear within 1–2 weeks.

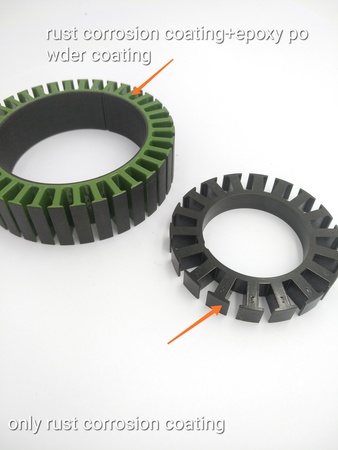

Standard Protection

For most industrial applications, applying an anti-rust treatment immediately after punching is enough to keep the cores clean and stable. This process slows down oxidation and ensures that the motor components maintain reliable performance.

When Special Protection is Needed

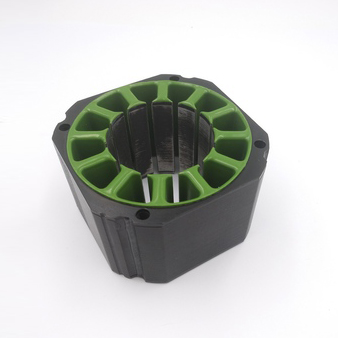

In certain environments—such as humid climates, water mist, or agricultural machinery—ordinary anti-rust methods are not sufficient. To meet these requirements, we use electrophoretic coating (E-coating) to provide stronger protection.

Electrophoretic Coating Features

-

Color: Black

-

Thickness: 0.013 – 0.025 mm (up to 0.1 mm)

-

Corrosion Resistance: Withstands a 24-hour salt spray test

This coating process gives the stator and rotor cores a uniform finish with excellent resistance to corrosion, making them suitable for harsh environments.

What We Offer

We supply stator and rotor cores with customized anti-rust treatments, including both standard surface protection and advanced electrophoretic spraying.

Our goal is to provide components that are durable, reliable, and ready for your application, whether for general industry or special equipment exposed to moisture.

Contact Us

If you need motor stator or rotor cores with professional anti-rust solutions, get in touch with us. We will provide a solution tailored to your working conditions and performance requirements.