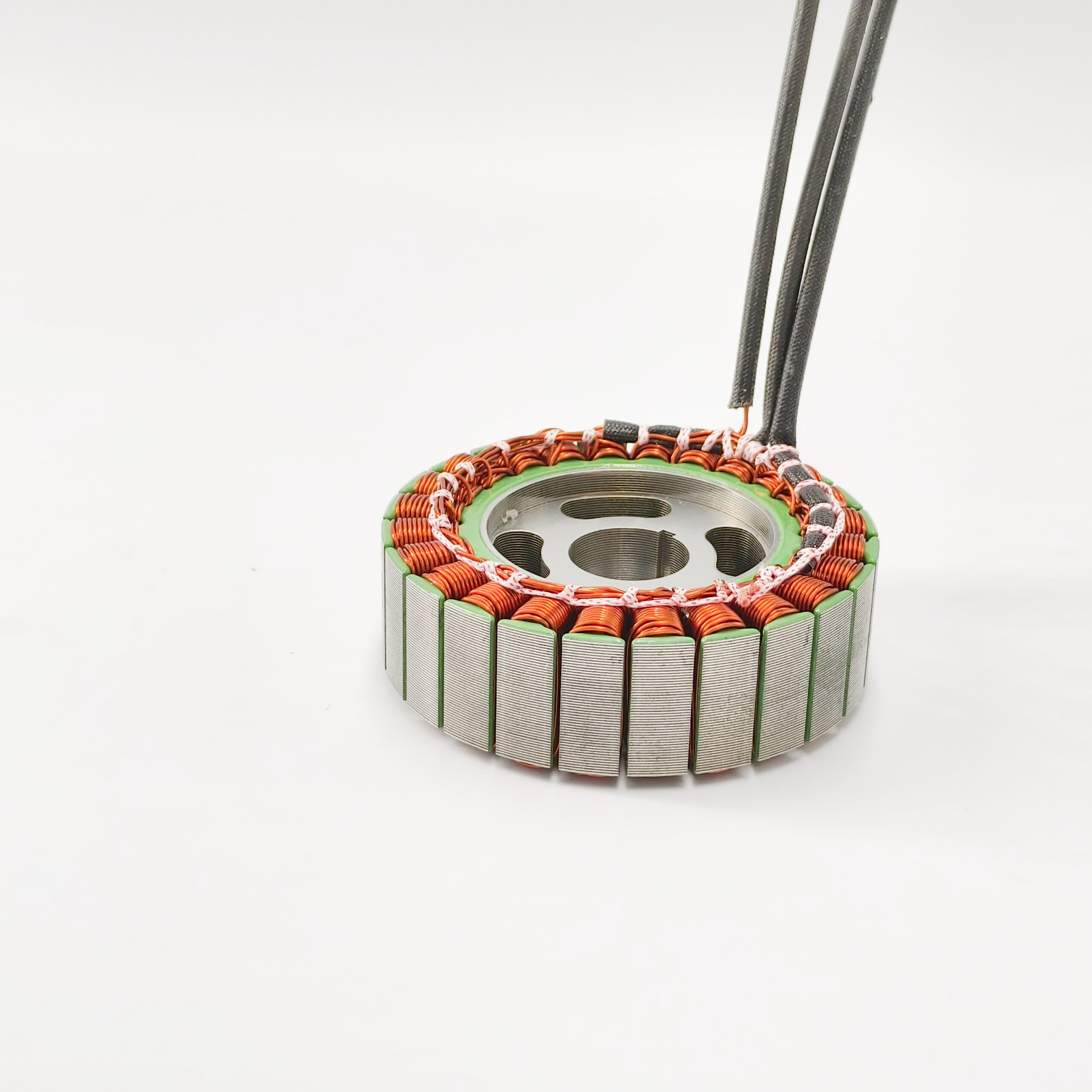

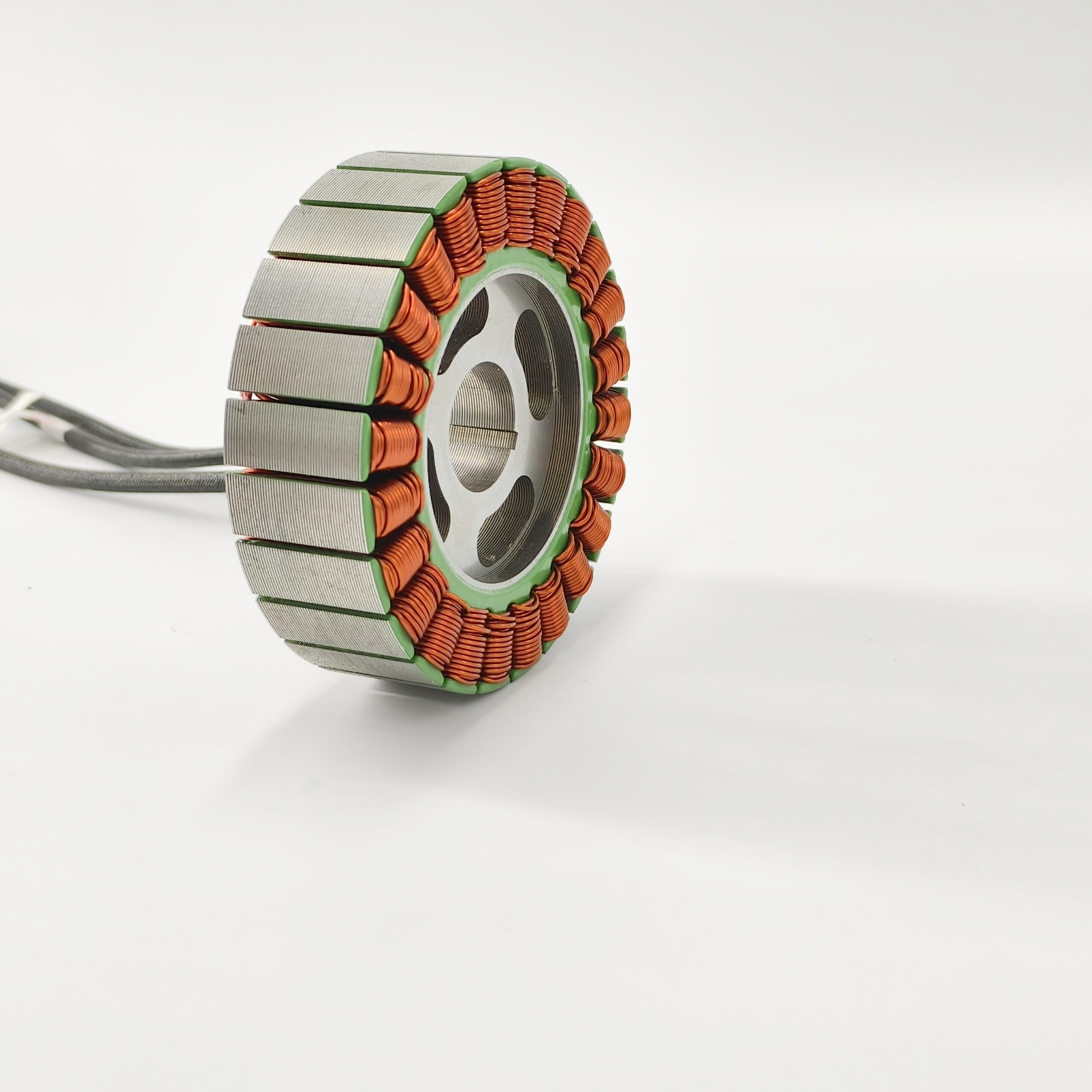

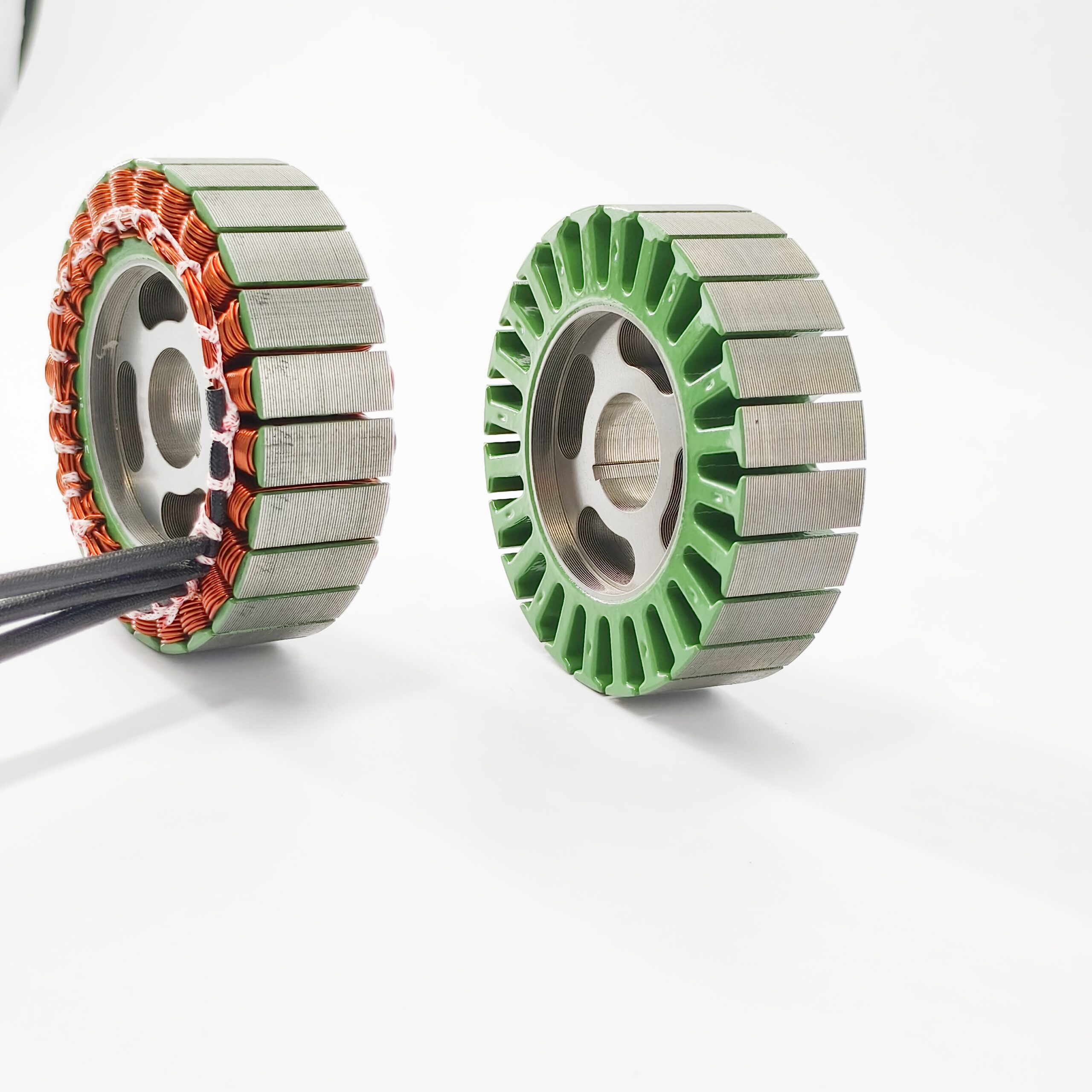

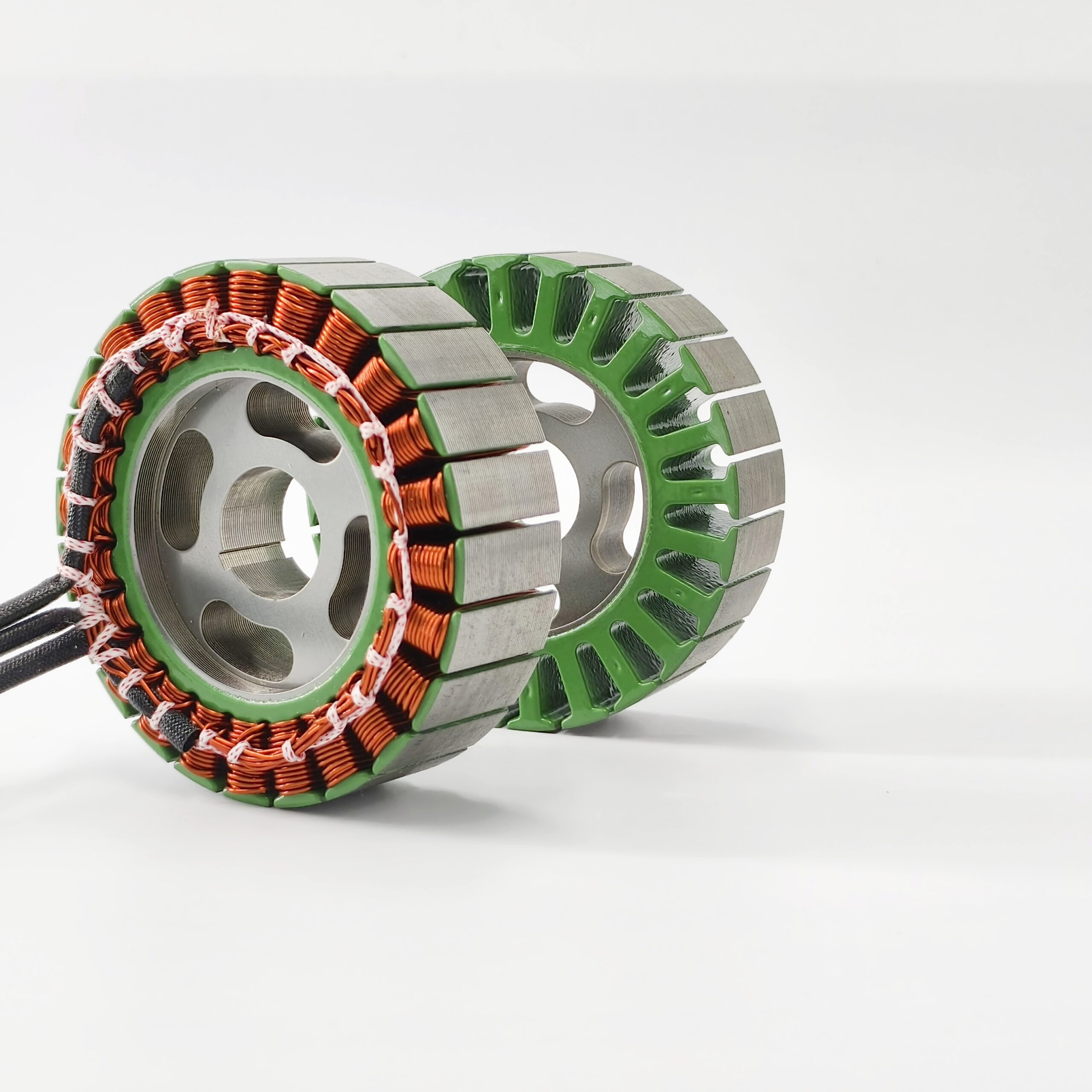

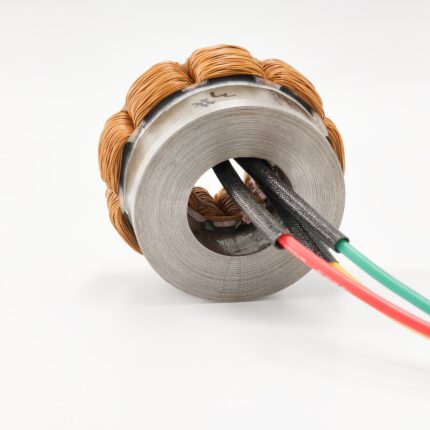

Customized winding:Internal winding/External winding/Special enameled wire winding/Concentrated winding/Distributed winding

Production process:

- Calculation of slot occupancy rate

- Try to go around

- Winding

- Wire connection

- Tin immersion

- Wire wrap shaping

- Electrical performance testing

- Varnish

- Test

- Packaging&Shipping

Quality control:

- Extremely high slot occupancy rate,The comprehensive slot filling rate of manual winding can reach 90%.

- Ultimate appearance,the wiring is beautiful, free of impurities, dirt, and Wuxi bead residue.

- Long-life,the enameled wire adopts Taiwanese brand manufacturers, and the insulation paint adopts ELENTAS brand to ensure the long-term 200 degree temperature resistance and safety of all products.

- Electrical Performance Guarantee,all products undergo 100% electrical performance testing before shipment, including phase resistance, phase inductance, insulation withstand voltage, turn to turn waveform, insulation resistance, etc.

Shipment:

- Size inspection:All shipped products undergo full-size inspection beyond AOL sampling standards.

- Appearance inspection:All products undergo 100% appearance inspection.

- Electrical performance testing: All wound products undergo strict electrical performance testing before and after immersion to ensure the absolute safety and reliability of the shipped stator core products.

Packaging&Shipping:

- Transportation: DHL, FEDEX, UPS and other three major courier companies are used for international express delivery.

- Inner packaging: All products are packaged with rust proof paper and treated with rust proof oil to ensure that they will not be corroded. The outer packaging is wrapped with 20mm thick anti-collision pearl cotton to ensure the safety of product transportation.

- Outer packaging:K-grade thick cardboard boxes or plywood wooden boxes to ensure product transportation safety.