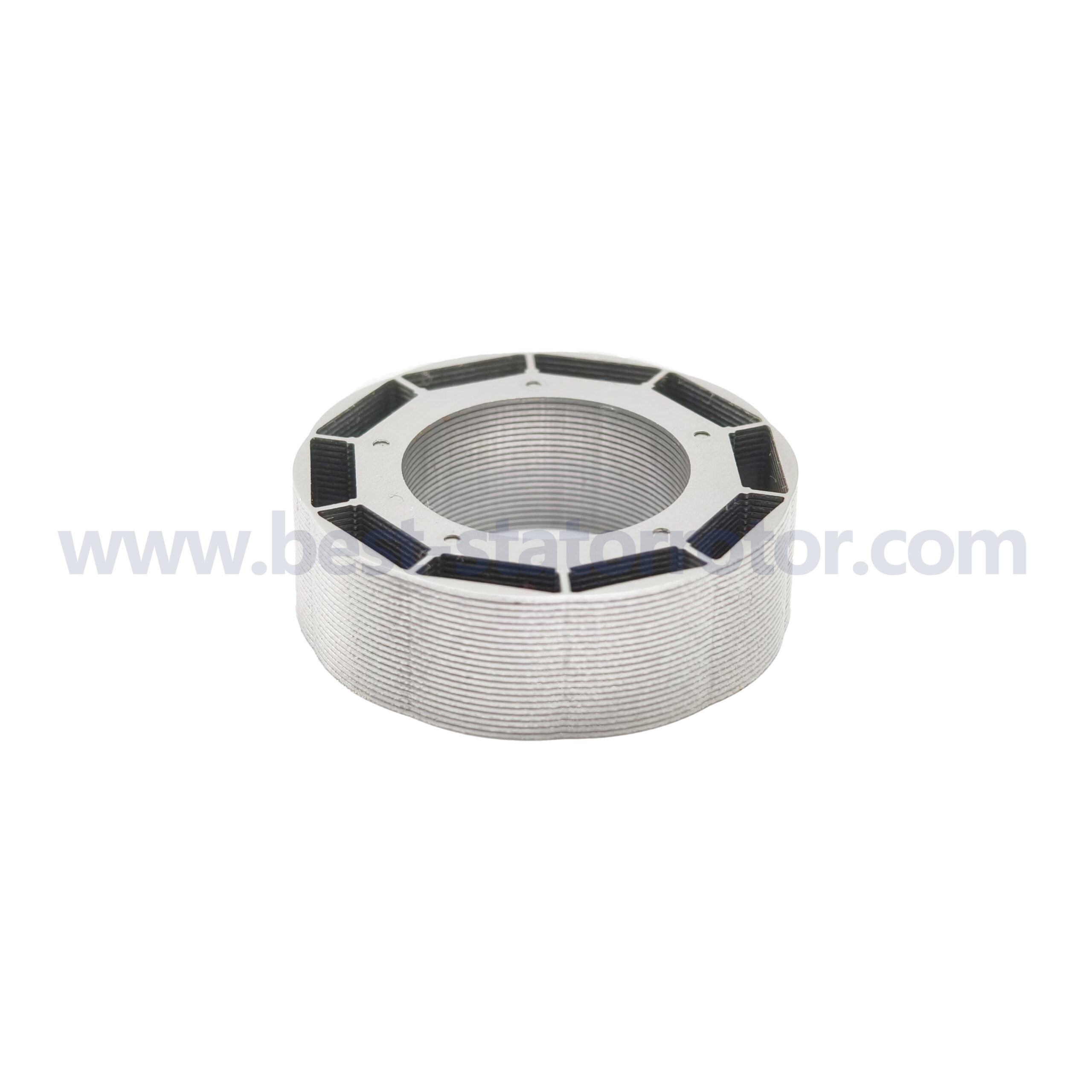

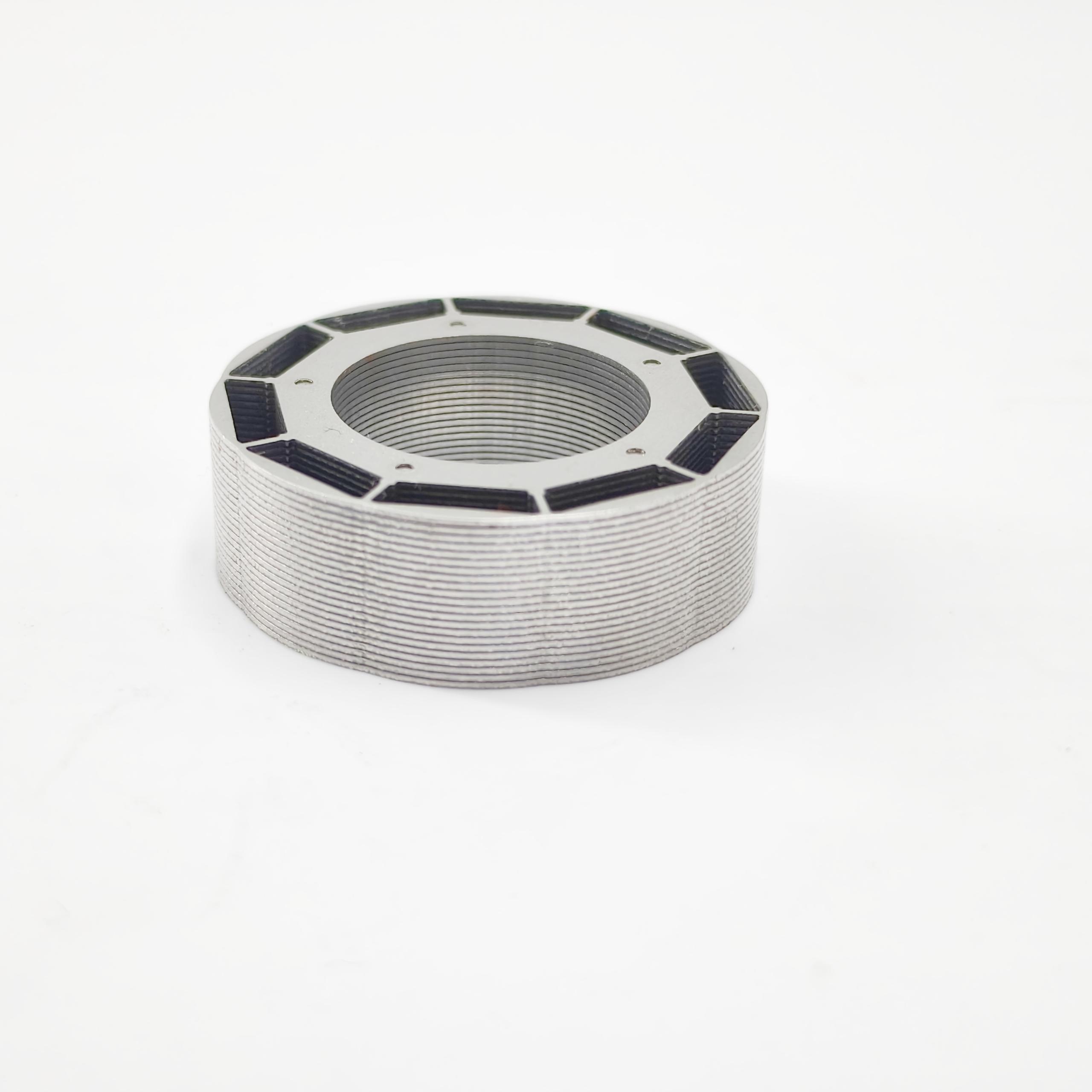

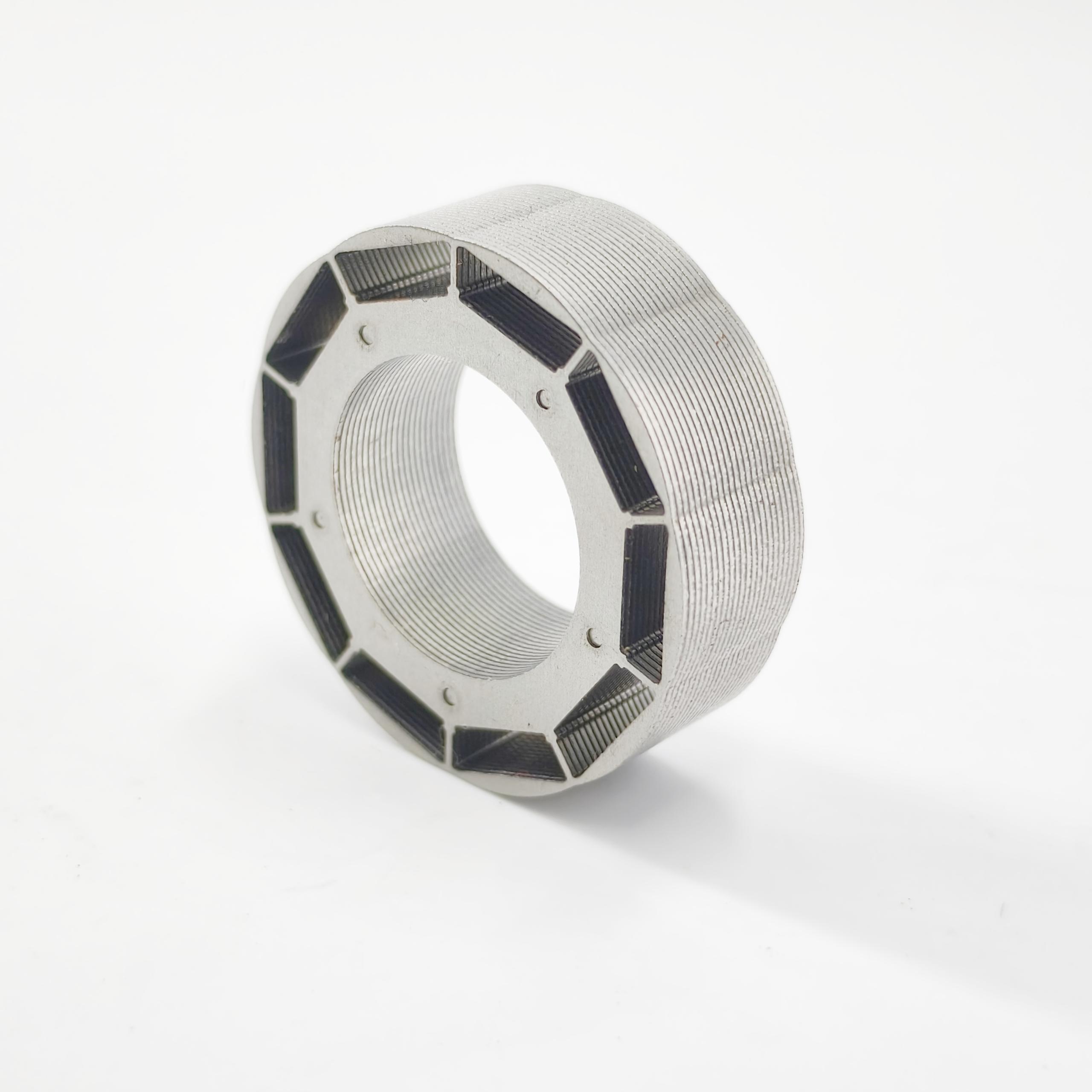

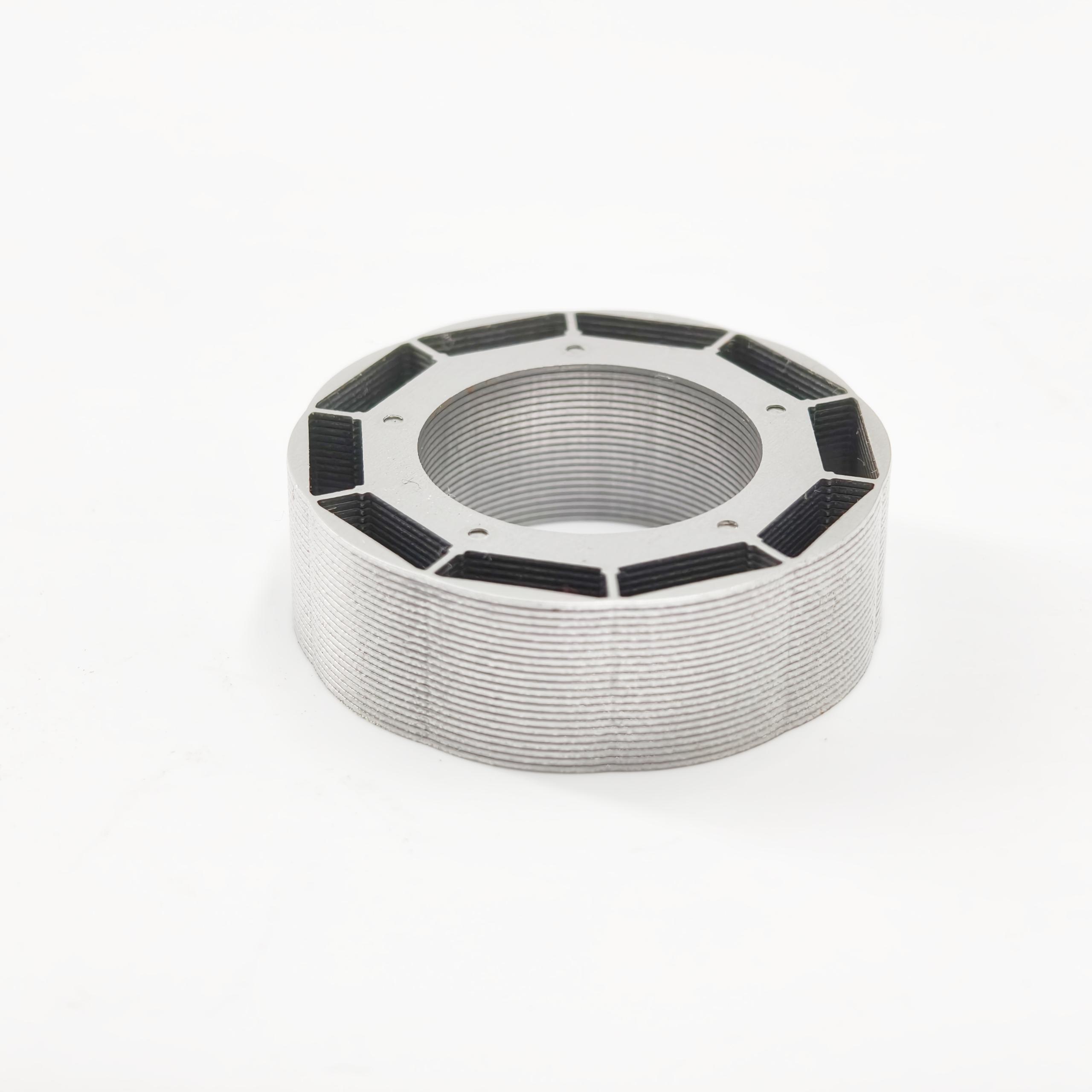

The Best team has 20 years of experience in motor design and development, and can provide the best stator and rotor stacking solutions based on your motor design and actual needs. Specifically, these solutions include riveting point self-fastening, laser welding, argon arc welding, adhesive bonding, rivet riveting, etc.

Enhance the comprehensive competitiveness of your motor with extremely high production efficiency and cost-effectiveness;

We can provide multiple types of mold designs based on your product size, silicon steel sheet thickness, and specific design;

The product size range is from 5mm to 800mm.

Manufacturing:

- Wire cutting

- Single punch die

- Composite mold

- Tungsten steel progressive die

Shipment:

- Size inspection:All shipped products undergo full-size inspection beyond AOL sampling standards.

- Appearance inspection:All products undergo 100% appearance inspection.

- Electrical performance testing: All wound products undergo strict electrical performance testing before and after immersion to ensure the absolute safety and reliability of the shipped stator core products.

Packaging&Shipping:

- Transportation: We use DHL, FEDEX, UPS and other major courier companies for international express delivery.

- Inner packaging: We package all products with rust-proof paper and treat them with rust-proof oil to ensure they will not be corroded. We wrap the outer packaging with 20mm thick anti-collision pearl cotton to ensure the safety of product transportation.

- Outer packaging:K-grade thick cardboard boxes or plywood wooden boxes to ensure product transportation safety.