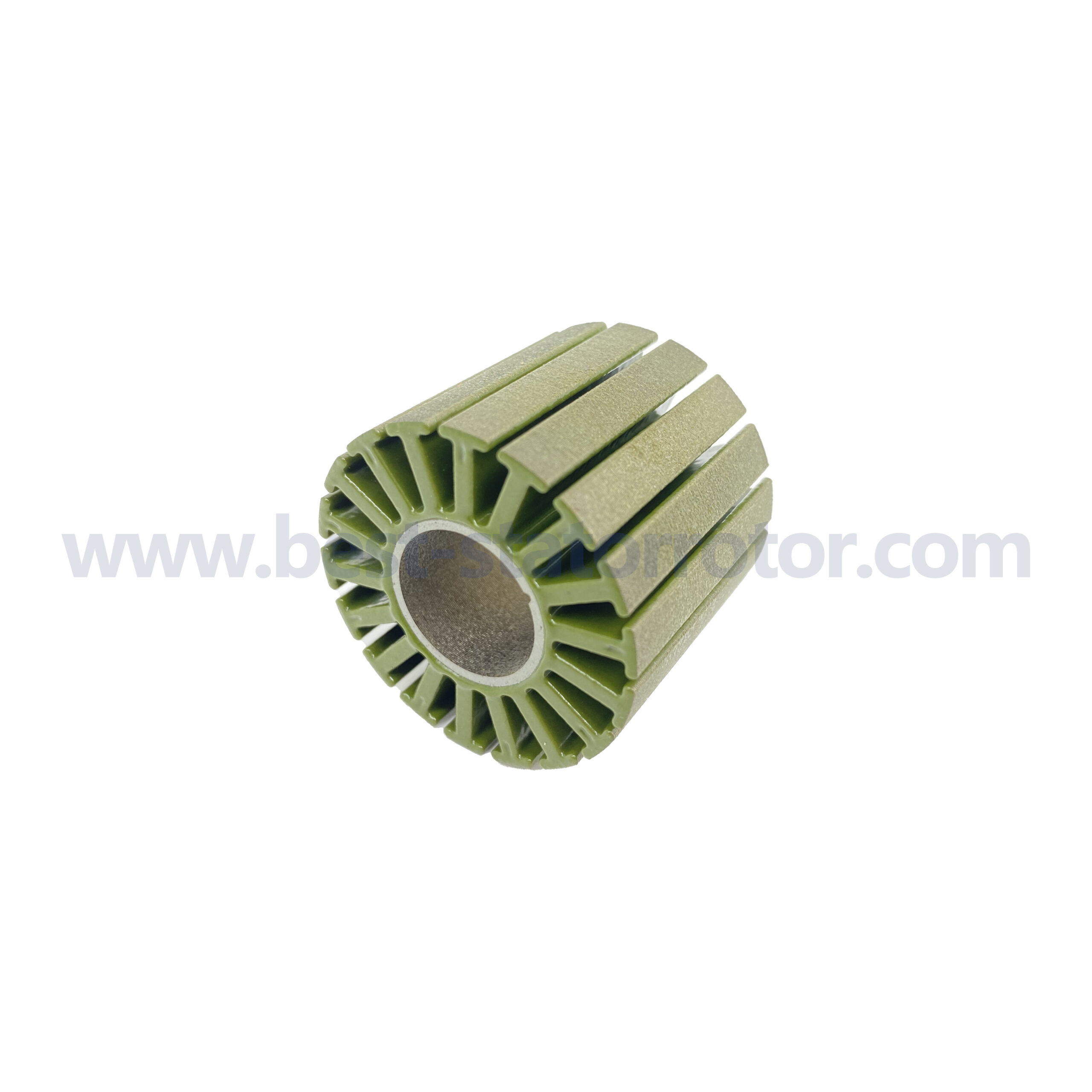

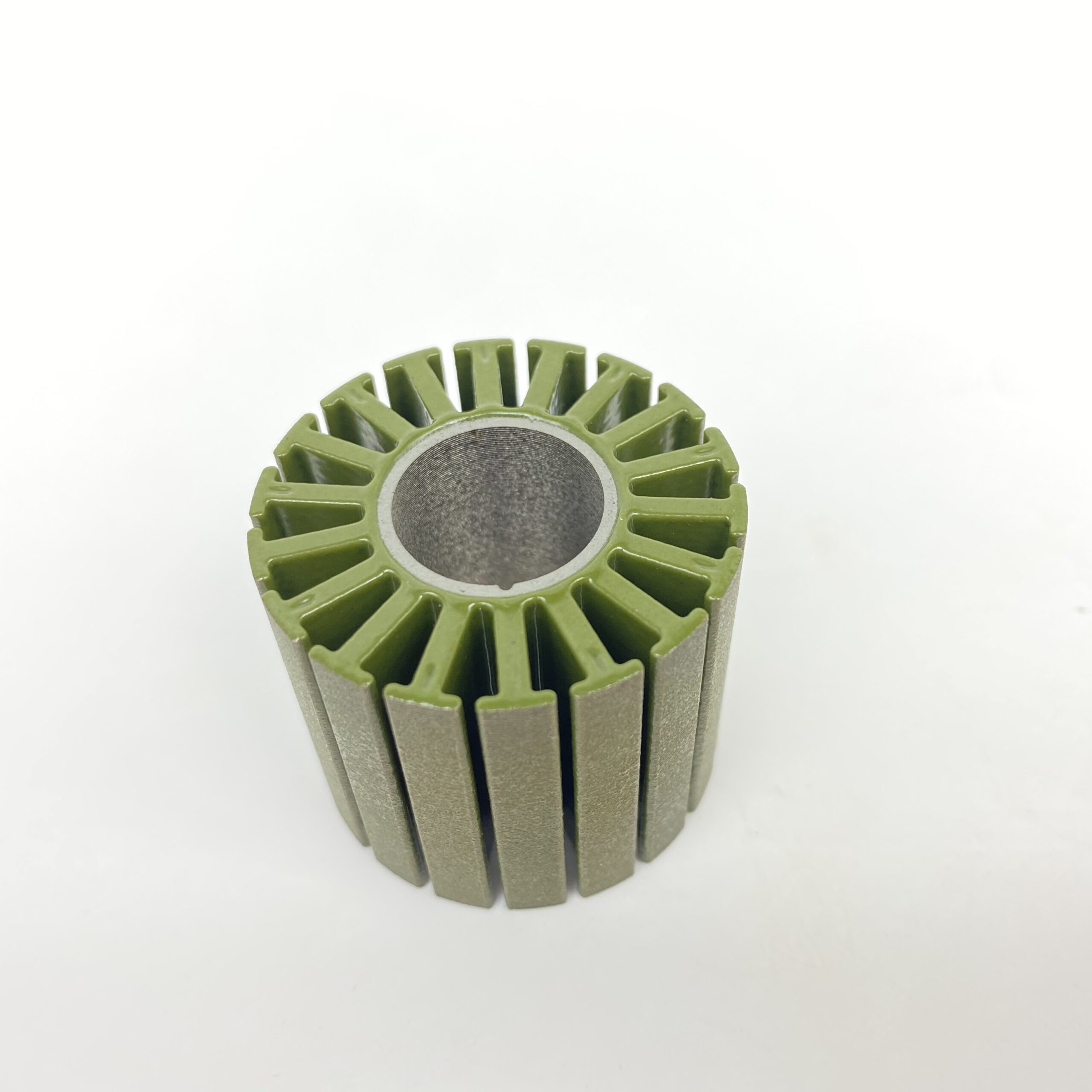

Stator and Rotor Lamination Solutions for Brushless Electric Motor

Brushless Electric Motor Introduction

A brushless electric motor is widely used in new energy vehicles, home appliances, and industrial equipment for its high efficiency, long service life, and low maintenance. The performance of a brushless electric motor depends greatly on the precision of its stator and rotor core, especially the use of high-quality silicon steel sheet and reliable lamination processes. Best provides advanced lamination and bonding solutions to help achieve stable performance and reduce energy loss in brushless electric motor applications.

Stator and Rotor Lamination Solutions

With over 20 years of experience in motor design and manufacturing, Best offers complete stator and rotor lamination solutions customized to your project needs. Available processes include:

-

Riveting point self-fastening

-

Laser welding

-

Argon arc welding

-

Adhesive bonding

-

Rivet riveting

These solutions improve motor performance, production efficiency, and cost-effectiveness, helping customers enhance competitiveness.

Mold Design Capabilities

We design and manufacture molds according to product size, silicon steel sheet thickness, and specific requirements. Product size range: 5mm to 800mm.

Manufacturing capabilities:

-

Wire cutting

-

Single punch die

-

Composite mold

-

Tungsten steel progressive die

Quality Control and Testing

All products go through strict inspection before shipment to ensure consistent quality:

-

Size inspection: 100% full-size inspection beyond AOL sampling standards.

-

Appearance inspection: 100% visual check to eliminate defects.

-

Electrical testing: All wound stator cores are tested before and after immersion to ensure electrical reliability.

Packaging and Shipping

Products are carefully packed to ensure safety during international transport:

-

Transportation: DHL, FedEx, UPS, and other major couriers.

-

Inner packaging: Rust-proof paper and anti-rust oil treatment, plus 20mm anti-collision pearl cotton for protection.

-

Outer packaging: K-grade thick cardboard boxes or plywood crates to guarantee safe delivery.