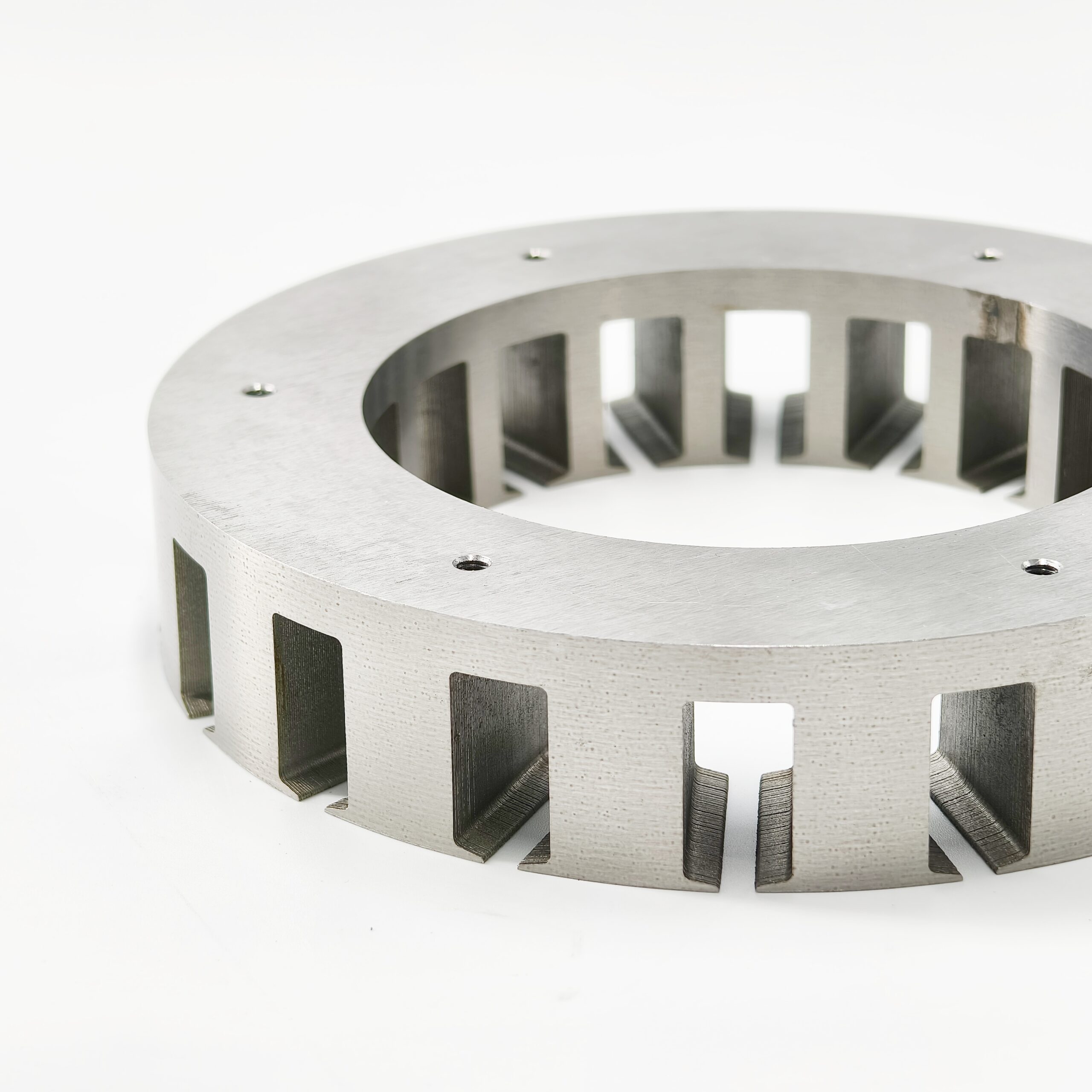

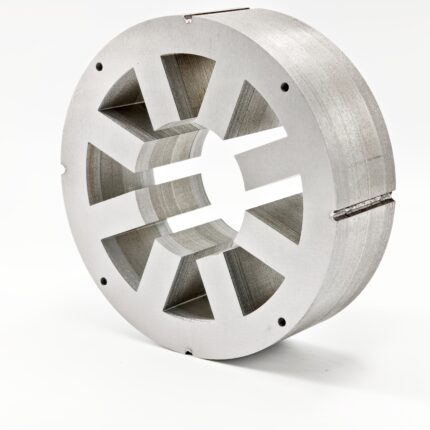

Axial flux motor is a rapidly growing market application in recent years, which is replacing and surpassing traditional motors in more and more fields with high efficiency, extremely high power density, and compact size; Application area:wind power generation, lifting equipment, oil well exploration equipment, new energy vehicles, etc.

Production process:

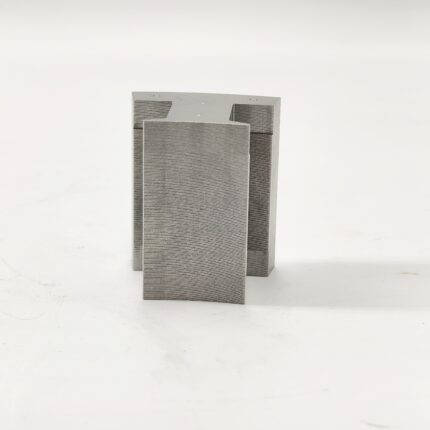

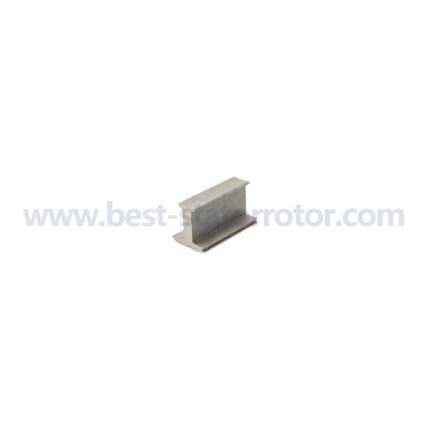

- Raw material segmentation

- Stamping+winding

- Plastic surgery+welding/bonding

- Drill

Shipment:

- Size inspection:All shipped products undergo full-size inspection beyond AOL sampling standards.

- Appearance inspection:All products undergo 100% appearance inspection.

- Electrical performance testing: All wound products undergo strict electrical performance testing before and after immersion to ensure the absolute safety and reliability of the shipped stator core products.

Packaging&Shipping:

- Transportation: DHL, FEDEX, UPS and other three major courier companies are used for international express delivery.

- Inner packaging: All products are packaged with rust proof paper and treated with rust proof oil to ensure that they will not be corroded. The outer packaging is wrapped with 20mm thick anti-collision pearl cotton to ensure the safety of product transportation.

- Outer packaging:K-grade thick cardboard boxes or plywood wooden boxes to ensure product transportation safety.